A powerful earthquake in Taiwan has rattled not only the island nation, but also the global technology industry. The 7.4 magnitude tremor, the strongest in 25 years, has caused casualties and infrastructure damage.

The earthquake significantly impacted the tech world by forcing Taiwan Semiconductor Manufacturing Company (TSMC), a vital supplier of advanced chips to companies like Apple, NVIDIA, and Qualcomm, to halt production at some of its facilities.

Sources familiar with TSMC’s operations have disclosed structural harm at its N3 fab in Tainan. Crucial components like beams and columns have been damaged, according to a Bloomberg report on April 3.

The situation has resulted in a complete shutdown of production, which includes Extreme Ultraviolet (EUV) machines essential for manufacturing processes below 7nm. Additionally, another facility in Hsinchu reported damaged pipelines and wafers that are unusable.

While the April 2023 earthquake in Taiwan caused initial worries, Apple and NVIDIA’s supply chains likely didn’t suffer significant long-term consequences. Here’s a breakdown:

Initial Concerns:

- The earthquake’s impact on chipmakers in Taiwan, particularly TSMC (a major supplier for both Apple and NVIDIA), raised concerns about production delays for Apple and NVIDIA products.

- Disruptions at TSMC and other Taiwanese suppliers could have affected the availability of components needed for iPhones, iPads, Macs, NVIDIA graphics cards, and other products.

Limited Disruption (Luckily):

- Fortunately, the impact turned out to be temporary. TSMC and other suppliers were able to resume operations relatively quickly, minimizing long-term disruptions.

- Several factors likely contributed to this:

- TSMC’s disaster preparedness: Their efforts in building earthquake-resistant facilities and having recovery plans likely helped them recover quickly.

- Diversified supply chains: Both Apple and NVIDIA likely have suppliers in various locations, reducing reliance on a single region like Taiwan.

Long-Term Considerations:

- The earthquake might have accelerated the trend of supply chain diversification in the chip industry. Governments and tech giants might invest in building new fabs (chip manufacturing facilities) in other regions to reduce dependence on Taiwan.

- Chipmakers may also prioritize even stronger disaster preparedness measures to minimize disruptions from future natural disasters.

Table of Contents

Potential impact on Apple

Concerns about potential delays in Apple’s product supply chain arise due to these disruptions, as TSMC supplies all of the custom silicon processors in Apple devices.

The uncertainty surrounding the impact of Apple’s upcoming product launches, such as the iPhone 15 Pro, persists. However, significant disruptions could potentially result in delays or limited availability.

There were concerns about the impact on Apple’s supply chain following a major earthquake in Taiwan in April 2023. Here’s a breakdown of the potential issues and how things played out:

Potential Disruptions:

- TSMC Impact: TSMC, a major supplier of Apple silicon chips, experienced production line stoppages and facility evacuations due to the earthquake. This could have led to delays in chip production for Apple devices.

- Beyond TSMC: Many other Apple suppliers also have facilities in Taiwan. The earthquake could have disrupted production of various components needed for Apple products.

- Overall Supply Chain: The entire supply chain, from chip manufacturers to final assemblers, could have been affected, potentially causing delays in iPhone, iPad, Mac, and other Apple product launches or production.

Actual Impact:

- Limited Disruption: Fortunately, the impact on Apple’s supply chain seems to have been temporary. TSMC and other suppliers were able to restore operations relatively quickly, with minimal long-term effects.

- Resilient System: Apple’s diversified supply chain, with suppliers in various locations, likely helped mitigate the impact of the earthquake in a single region.

Production Delays:

- Chip Disruptions: TSMC is a major supplier of chips for Apple products. An earthquake causing significant damage to TSMC facilities could lead to delays in iPhone, iPad, and Mac production.

- Component Shortages: Beyond chips, other Apple product components could be affected if Taiwanese suppliers experience disruptions.

Financial Impact:

- Production Cost Increases: Delays and disruptions could increase production costs for Apple.

- Lost Sales: If Apple can’t meet product demand due to supply chain issues, they could lose sales.

Reputational Impact:

- Delays in product launches or availability could negatively impact Apple’s reputation.

TSMC’s disaster preparedness and recovery efforts

With a history of disaster preparedness, TSMC implemented rigorous seismic management measures following a major earthquake in 1999.

Furthermore, the company has promptly taken action to assess the damage and initiate recovery procedures, with expectations of some production lines resuming operation soon.

TSMC, recognizing its critical role in the global chip supply chain, has implemented a comprehensive disaster preparedness and recovery program. Here’s a breakdown of their key strategies:

Preparation:

- Hazard Identification: TSMC proactively identifies potential disaster risks, including earthquakes, fires, and utility outages [1].

- Enhanced Building Standards: They invest in building facilities that can withstand seismic activity. This includes installing seismometers to detect tremors and designing structures to minimize damage [4].

- Securing Equipment: Machinery within the fabs (fabrication plants) is secured to prevent falling or shifting during an earthquake [4].

- Business Continuity Plans: TSMC establishes detailed plans outlining actions for various disaster scenarios. These plans ensure a swift and coordinated response to minimize downtime [1, 5].

- Training and Drills: TSMC conducts regular drills and training programs for employees on emergency procedures and evacuation protocols [3]. This empowers staff to react effectively during a crisis.

- All-Hazard Approach: TSMC has adopted a comprehensive approach to disaster management, considering various potential threats beyond earthquakes [2].

Recovery:

- Emergency Response Teams (ERTs): Dedicated teams are trained to respond swiftly and assess damage after a disaster [5].

- Rapid Restoration: TSMC prioritizes the quick restoration of critical equipment and infrastructure to resume production as soon as possible [4].

- Supplier Network Management: Collaboration with suppliers ensures a coordinated recovery effort throughout the supply chain [2].

Effectiveness:

- April 2024 Earthquake: TSMC’s efforts were put to the test during the April 2024 earthquake. Fortunately, due to their preparedness, they were able to recover over 70% of their wafer fabrication equipment within just 10 hours [4]. This swift response minimized disruptions to the global chip supply chain.

Global chip shortage concerns rise

Being one of the world’s largest makers of advanced chips, TSMC, along with Taiwan as a whole, produces a majority of the world’s semiconductors. This earthquake compounds the strain on the tech supply chain, prompting concerns about potential disruptions.

Nevertheless, TSMC’s efforts to recover and Apple’s supply chain management strategies could assist in mitigating the immediate effects.

While the tech industry is still assessing the full extent of the damage and the impact, this event highlights how susceptible chip production is to natural disasters.

Here’s a quick rundown of what happened:

- Earthquake Impact: The 7.4 magnitude earthquake caused tremors in key chip manufacturing areas of Taiwan. This raised worries about potential damage to factories and disruptions in production.

- Taiwan’s Importance: Taiwan is a global leader in semiconductor manufacturing, and any disruptions there can have ripple effects throughout the tech industry.

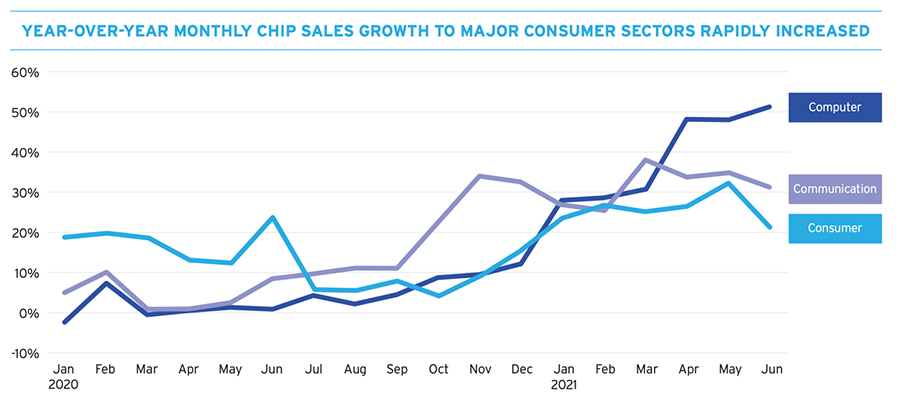

- Chip Shortage History: The world had already been grappling with a chip shortage for a while, affecting everything from cars to consumer electronics. This earthquake added fuel to those concerns.

Limited Disruption (Luckily)

- Resumption of Production: Thankfully, initial reports indicated that the impact wasn’t as severe as initially feared. Chipmakers like TSMC were able to resume production fairly quickly, with minimal long-term disruptions.

- Focus on Recovery: The focus in Taiwan shifted towards recovery efforts, but the episode served as a reminder of the chip industry’s vulnerability.

Long-Term Effects

- Supply Chain Diversification: The earthquake likely pushed governments and tech giants to further explore diversifying chip production beyond Taiwan. This could involve building new manufacturing plants in other regions.

- Preparedness Measures: Chipmakers may also invest in more robust disaster preparedness measures to minimize disruptions from future natural disasters.

Overall, the Taiwan earthquake caused a temporary spike in concerns about the chip shortage. While things went back to normal relatively quickly, it highlighted the need for a more resilient and geographically diverse chip supply chain.

Potential Impact of Taiwan Earthquake on NVIDIA

NVIDIA, as a major player in the global semiconductor industry, is highly susceptible to disruptions in the supply chain. Taiwan is a critical hub for semiconductor manufacturing, and any earthquake-related damage to facilities could have significant repercussions for NVIDIA.

Here are some potential impacts:

- Chip Shortages: Damage to semiconductor manufacturing facilities in Taiwan could lead to shortages of essential components for NVIDIA’s GPUs. This could result in reduced production, higher costs, and potentially delayed product launches.

- Supply Chain Diversification: The earthquake might accelerate NVIDIA’s efforts to diversify its supply chain by establishing manufacturing facilities or partnerships in other regions.

- Financial Impact: Disruptions in the supply chain can lead to financial losses due to increased production costs, inventory shortages, and potential decline in sales.

- Market Instability: The earthquake could create uncertainty in the semiconductor market, leading to fluctuations in chip prices and affecting NVIDIA’s overall business operations.

While the extent of the impact depends on the severity of the earthquake and the damage incurred by semiconductor manufacturers, NVIDIA, like other tech giants, is likely to experience challenges in the short to medium term.

Taiwan’s Seismic Challenge

Taiwan is situated in a seismically active region, making it prone to earthquakes. The island’s geographical location at the meeting point of two tectonic plates—the Eurasian and Philippine Sea plates—contributes to its frequent seismic activity.

A History of Tremors

Taiwan has experienced numerous earthquakes throughout history, some of which have caused significant damage and loss of life. The most notable earthquake was the 1999 Jiji earthquake, which resulted in widespread destruction and over 2,000 fatalities.

Preparedness and Resilience

Despite the challenges posed by earthquakes, Taiwan has made significant strides in disaster preparedness and response. The government has implemented strict building codes and conducted regular earthquake drills to educate the public about safety measures.

Know about NVIDIA

NVIDIA: A Titan in the Tech World

NVIDIA is a global technology company renowned for its expertise in designing and producing graphics processing units (GPUs). While initially focused on the gaming industry, the company has expanded its reach to encompass a vast array of sectors, including artificial intelligence, data centers, and autonomous vehicles.

From Gaming to AI

NVIDIA’s journey began with a focus on enhancing the visual experience of computer games. The company’s GPUs revolutionized the gaming industry by delivering stunning graphics and performance. However, it was the realization of the GPU’s potential beyond gaming that propelled NVIDIA to new heights.

The company’s GPUs proved to be exceptionally well-suited for handling the complex computations required for artificial intelligence. This discovery led to NVIDIA becoming a dominant player in the AI hardware market. Today, its GPUs power some of the world’s most advanced AI systems, driving breakthroughs in fields such as image recognition, natural language processing, and self-driving cars.

In addition to GPUs, NVIDIA has diversified its product portfolio to include:

- Tegra processors: Designed for mobile devices and embedded systems.

- Data center platforms: High-performance computing solutions for businesses and research institutions.

- Autonomous vehicle platforms: Hardware and software for self-driving cars.

NVIDIA’s commitment to research and development has been instrumental in its success. The company continues to push the boundaries of technology, delivering innovative solutions that shape the future.

Conclusion

Here’s the conclusion regarding the impact of the Taiwan earthquake (April 2023) on Apple and NVIDIA’s supply chains:

Limited Disruption:

- Despite initial concerns, the earthquake’s impact on Apple and NVIDIA’s supply chains proved to be temporary.

- TSMC and other suppliers were able to resume production relatively quickly, minimizing long-term disruptions.

Factors Contributing to Minimal Disruption:

- TSMC’s Preparedness: TSMC’s disaster preparedness measures, like building earthquake-resistant facilities and having recovery plans in place, likely helped them bounce back quickly.

- Diversified Supply Chains: Both Apple and NVIDIA likely benefited from having diversified supplier networks, potentially including manufacturers outside Taiwan. This redundancy may have mitigated the impact of a single region’s disruption.

Long-Term Considerations:

- Supply Chain Diversification Trend: The earthquake likely reinforced the push for more geographically diverse chip production. Governments and tech companies might invest in building new fabs in other regions to lessen reliance on Taiwan.

- Continued Focus on Preparedness: Chipmakers will probably continue to invest in disaster preparedness to minimize future disruptions.

Disclaimer ||

The Information provided on this website article does not constitute investment advice ,financial advice,trading advice,or any other sort of advice and you should not treat any of the website’s content as such.

Always do your own research! DYOR NFA

Coin Data Cap does not recommend that any cryptocurrency should be bought, sold or held by you, Do Conduct your own due diligence and consult your financial adviser before making any investment decisions!

Leave feedback about this